Understanding Cable Clamps and Their Role

Definition and Core Functions of Cable Clamps

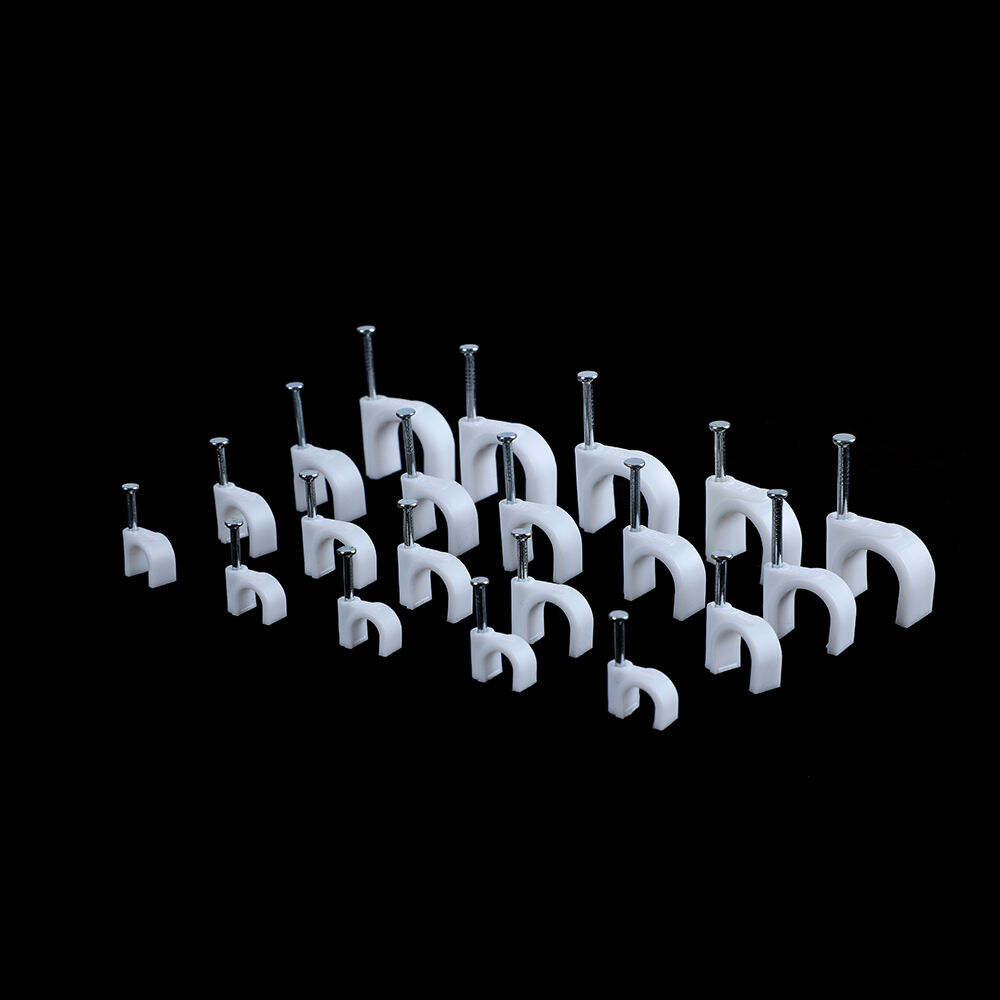

Cable clamps serve as mechanical fasteners that hold cables in place so they don't get loose or tangled. They do more than just keep things organized though. Good quality clamps also make wiring look neater while protecting cables from dirt, moisture, and other environmental damage. We see these little devices everywhere actually - in homes, offices, factories, anywhere there are wires running around. Without proper clamping, messy cables can become safety issues too. A properly secured setup prevents short circuits and reduces fire risks, something every electrician knows is important when working on installations.

Cable clamps really help keep things organized and make installations look much better overall. When cables stay untangled and protected, there's less chance of electrical problems happening down the road. That makes these little devices pretty important for anyone dealing with wires, whether it's just running some cables behind a TV stand at home or managing massive networks in factories and data centers. Most electricians will tell you that proper cable management isn't just about looks either it actually saves time and money when troubleshooting later on.

Why Proper Clamp Selection Impacts Safety and Efficiency

Getting the right cable clamp matters a lot when it comes to keeping installations safe and running smoothly. When people pick the wrong clamp, cables get damaged over time, and this can cause all sorts of problems down the road like electrical failures or even safety issues that put both machines and workers at risk. The good news is that proper clamps make installations much more reliable. They help keep everything connected properly so systems don't break down unexpectedly during operation.

Studies indicate companies that focus on picking good quality clamps tend to have far fewer safety problems, which makes sense when working in places where mistakes can be costly. Nylon cable ties work well for most situations, but stainless steel options hold up better in harsh industrial settings where cables get exposed to chemicals or extreme temperatures. Getting this right matters because poor clamping leads to damaged wiring and disrupted operations across the board. Spending money on decent clamps isn't just about keeping things running smoothly it's actually smart risk management for anyone dealing with electrical systems or fiber optic networks where even small failures can cause major headaches down the line.

Types of Cable Clamps for Different Applications

Stainless Steel Cable Ties: Durability in Harsh Environments

When durability matters most and corrosion is a concern, stainless steel cable ties come through every time. Built to last in harsh environments, these ties keep their strength intact despite exposure to intense pressures and fluctuating temperatures. Think about places where failure just won't do: offshore drilling platforms, chemical processing facilities, or anywhere saltwater might be an issue. Real world experience shows that switching to stainless steel can cut down on replacement frequency and repair work since they simply don't break down as fast as other options. Maintenance crews report spending less time fixing things and more time getting actual work done. Compared to plastic or standard metal alternatives, stainless steel holds its own against abrasion, UV damage, and chemical exposure while still delivering real savings over time.

Nylon Cable Ties: Flexibility and Cost-Effective Solutions

Nylon cable ties are pretty flexible and light weight, which is why they work so well in so many different situations. People use these all the time at home and in offices because they don't break the bank while still getting the job done. When something needs to be light but durable, nylon ties perform really well. Plus, they can handle exposure to sunlight and chemicals, so they last longer in outdoor or industrial settings where other materials might fail. A lot of folks who have tried them say they're great for keeping wires organized without spending a fortune on fancy solutions. That combination of bendy enough to work with almost anything yet cheap enough to buy in bulk has made nylon cable ties pretty much standard equipment for anyone dealing with cables regularly.

Specialized Clamps: Suspension and Parallel Groove Designs

Cable clamps come in different styles, including suspension and parallel groove types, each made for particular jobs that boost both safety and work efficiency. Suspension clamps work great when cables need to hang overhead, giving strong support so vertical lines stay put and cables don't get damaged from movement. For situations where lots of wires need grouping together, parallel groove clamps make life easier during setup and ongoing maintenance. These specialized tools matter a lot in fields like telecom and building projects, where complicated wiring setups demand specific solutions instead of one-size-fits-all approaches. Anyone working on serious cable installations knows firsthand how much difference it makes to pick the correct clamp type for what needs doing.

Material Showdown: Stainless Steel vs. Nylon

Strength and Corrosion Resistance of Stainless Steel

Stainless steel cable ties have a reputation for being super strong and resistant to rust, which makes them great for lasting a long time without breaking down. Because they don't corrode easily, these ties work really well in places where things need to hold up over years of wear and tear, think factories or boats out at sea. Most good quality stainless steel ties will actually have some sort of certification showing they've been tested against tough conditions, so people know they can trust them when it matters most. From what many professionals see in the field, stainless steel tends to handle stress much better than regular nylon ties do, particularly when there's constant tension or vibration involved. That's why so many industries rely on them whenever equipment needs to stay secure despite whatever weather or mechanical forces might be thrown at it.

UV and Chemical Resistance of Nylon Cable Ties

Nylon cable ties stand out because they resist UV rays and most common chemicals pretty well, which explains why they work so great in all sorts of environments. That durability is why mechanics love using them on cars and construction workers rely on them outdoors where weather conditions constantly change. Tests have actually shown these plastic ties hold up against sun damage and chemical contact much better than other materials when exposed over time. Because of this toughness, manufacturers across different sectors keep turning to nylon cable ties as go-to solutions for organizing wires and securing equipment in both industrial and consumer settings every day.

Choosing Between Suppliers and Manufacturers

Picking good suppliers for cable ties matters a lot if we want those products to actually hit the required industry standards and specs. The better companies usually come with all sorts of quality certificates behind them something we see quite often among leading makers of stainless steel cable ties. When looking around for options, folks should really check out things like how strong the materials are, what they cost, and whether the company stands behind their product when problems arise. Taking time to do this kind of detailed comparison makes sure whatever cable ties get selected work properly for whatever job they're needed for, plus they tend to last much longer without breaking down over time.

5 Factors to Consider When Selecting a Cable Clamp

Load Capacity and Tensile Strength Requirements

Picking out the right cable clamp starts with figuring out what kind of load capacity we need for whatever job we're doing. The clamp needs to hold up against all those forces without breaking down because otherwise nobody wants their setup failing mid-project. Tensile strength matters quite a bit here too. Most folks just glance at specs but really should check if manufacturers follow proper industry standards when making their products. That way we avoid situations where cables snap or worse yet cause accidents on site. For anyone wanting proof about how well clamps perform over time, running some basic dynamic load testing makes sense. Just grab a few samples and put them through their paces under various stress scenarios. After seeing results firsthand, most people feel much better knowing exactly what they're working with before installation begins.

Environmental Exposure (Temperature, Moisture, Chemicals)

When thinking about where a cable clamp will be installed, environmental factors matter a lot. We need to consider things such as extreme temperatures, how much moisture there might be, plus possible contact with chemicals. Stainless steel and good quality nylon tend to work best since they stand up well to all these challenges. Most people working in industrial settings know that checking and maintaining clamps regularly makes sense, particularly if they're going to sit in tough environments for long periods. Doing this kind of maintenance ahead of time means problems don't get worse before anyone notices them, which naturally helps the clamp last longer than it otherwise would.

Compliance with Industry Standards and Certifications

When picking out cable clamps, sticking to industry standards and getting proper certifications isn't something companies can skip over. Not following these guidelines might cause problems down the road both operationally and legally speaking. Certifications from organizations such as ISO and ASTM help manufacturers maintain consistent quality throughout their production lines. For businesses, meeting these requirements serves two main purposes: protecting against potential liabilities and maintaining trust with clients and partners alike. Choosing certified products ultimately protects financial investments while keeping day-to-day operations running without those frustrating surprise breakdowns that nobody wants.

Installation Guidelines and Maintenance Tips

Step-by-Step Clamp Installation Process

Getting those cable clamps installed right takes some careful planning if we want them to last and work properly. First thing's first, check out where exactly they need to go and gather all the necessary tools for the job. Doing this upfront inspection helps spot problems before they become headaches later on, like when there just isn't enough room or weather conditions could cause issues down the road. Once that's sorted, actually putting the clamps in place follows a pretty straightforward process. Space them out evenly along the cable so no one section bears too much weight, otherwise we risk creating weak spots that will eventually fail. Don't forget about how tight to make those bolts either – too loose and the whole setup becomes unstable, too tight and we might actually damage the cables themselves. With everything positioned correctly and secured just right, these installations tend to perform better over time and require fewer repairs in the long run.

Avoiding Common Mistakes in Cable Management

Cable management problems happen all the time, especially when people over tighten bundles or leave too much space between them. These simple mistakes can really mess up how well the whole system works. When someone cranks down on cables too hard, it actually damages them inside. And if there's not enough support along the way, cables just droop down everywhere which makes connections unreliable at best. Training matters a lot here. Workers need hands on instruction so they spot potential problems during setup rather than after something breaks. Regular check ups also make a big difference. Looking things over every few months catches small issues before they become major headaches. The whole point isn't just getting everything installed correctly from day one either. Keeping those cables in good shape through routine maintenance stops them from wearing out faster than they should, saving money in the long run.