Material Composition: How Polymer and Metal Choices Define Cable Tie Performance

Nylon 6/6 vs. Stainless Steel: Tensile Strength, Thermal Stability, and Corrosion Resistance

Nylon 6/6 cable ties can handle between 120 to 250 pounds of tension and bend pretty well too, which makes them great for most indoor jobs where there isn't much stress involved. However these ties start breaking down when temperatures go past around 185 degrees Fahrenheit (that's about 85 Celsius) and they just won't hold up if left out in sunlight for long periods or exposed to strong chemicals. Stainless steel cable ties tell a different story altogether though. They can take loads exceeding 1000 pounds and work just fine across an amazing temperature range from minus 40 all the way up to 1200 degrees Fahrenheit (or minus 40 to 650 Celsius). These metal ties keep their shape even after repeated heating and cooling cycles, survive being submerged in seawater, and perform reliably in tough chemical settings such as those found on offshore oil platforms or inside wastewater treatment facilities. Nylon might stand up against some basic solvents, but stainless steel simply doesn't corrode like regular plastic does, so it avoids failures caused by rust that would quickly destroy nylon components instead.

High-Performance Polymers (PEEK, ETFE, POM): UV, Chemical, and Vibration Resistance for Harsh Environments

At the top end of engineered polymers for tough applications stand PEEK, ETFE, and POM. Take PEEK for instance it keeps its strength even when temperatures hit around 480 degrees Fahrenheit (that's 250 Celsius) and stands up against harsh chemicals like acetone and those chlorinated hydrocarbons without getting all swollen or brittle. Then there's ETFE with its special fluoropolymer structure that really holds up against sunlight. We've seen these materials last over 15 years outside without fading much or losing their tensile strength. And don't forget about POM which brings together stiffness, low friction characteristics, plus good resistance to fatigue. This makes it great for places where regular plastic parts would wear out from constant movement and vibration, think about wiring harnesses inside airplanes or components near engines. Unlike cheaper plastics, these advanced materials won't crack, deform, or change shape over time when exposed to continuous stress conditions.

Fire-Retardant, Halogen-Free, and Biodegradable Cable Tie Options for Safety and Sustainability Compliance

Cable ties rated for UL94 V-0 fire resistance will typically put themselves out within around ten seconds when exposed to flames. This feature is really important for stopping fires from spreading inside those tight electrical boxes or server rooms where heat can build up quickly. Many manufacturers now offer versions without halogens, which means they don't release those dangerous hydrogen halides or dioxins when burned. These meet all the necessary standards set by the EU RoHS directive and IEC 61249-2-21 specs, so they work well in places like subway stations and highway tunnels where public safety matters most. Some newer biodegradable models made from plant based materials such as PLA or PHA break down completely after about five years if placed in industrial compost facilities. This cuts down on landfill waste by roughly 80 percent compared to regular nylon ties. As governments worldwide keep raising their safety bars and companies become more focused on environmental goals, these specialized cable tie options are becoming increasingly common across various industries.

Mechanical Reliability: Tensile Strength, Tension Control, and Load-Bearing Consistency

Loop Tensile Strength (LTS) vs. Real-World Dynamic Loads: Why Lab Ratings Aren’t Enough

The Loop Tensile Strength (LTS) rating measures how much force something can hold when pulled straight, but what really matters in actual applications is how materials behave under changing conditions. Standard lab testing doesn't account for things that happen in real environments, such as vibrations that come from machines running, temperature changes that make materials expand or contract over time, and sudden impacts that stress components differently than controlled tests do. These factors actually cause materials to wear out faster than expected. When looking at stress patterns, engineers find that real world forces often cut down on the actual strength by around 30 to maybe even 40 percent compared to those neat lab numbers. For industries working with aircraft parts, robotic systems, or big construction equipment, understanding this difference becomes really important. That's why smart designers always build in extra capacity, sometimes going for fasteners rated twice what they think they need just to be safe. Maintenance records across manufacturing plants back this up too - most problems with cables breaking or coming loose aren't because someone overloaded them beyond their specs, but because those unexpected dynamic forces nobody modeled properly got to them first. So relying solely on LTS figures won't cut it when designing systems where failure isn't an option.

Over-Tightening Prevention and Non-Damaging Tension: Protecting Sensitive Cables and Harness Integrity

Too much tightening still causes most problems with insulation damage, especially when dealing with those tricky low voltage connections, fiber optics, and coax cables. Newer high quality cable ties now come with special features built in to limit how tight they can get during installation. These include things like ratchets that break off if pulled too hard or little pawl mechanisms calibrated for just the right amount of pressure around 2 to 4 psi. That's sufficient to hold everything together securely while avoiding compression issues that might ruin insulation layers or mess up sensitive outer coatings. Some manufacturers even produce smooth edge nylon versions specifically designed to reduce abrasion, which helps maintain signal quality by preventing tiny scratches on fiber surfaces. Testing done by third parties shows these properly tensioned systems last about three times longer than old fashioned methods where people just grab whatever tie is handy. Makes sense really, since smart mechanical design works better than simply cranking down until something breaks.

Design Intelligence: Ratcheting Precision, Structural Reinforcement, and Application-Specific Ergonomics

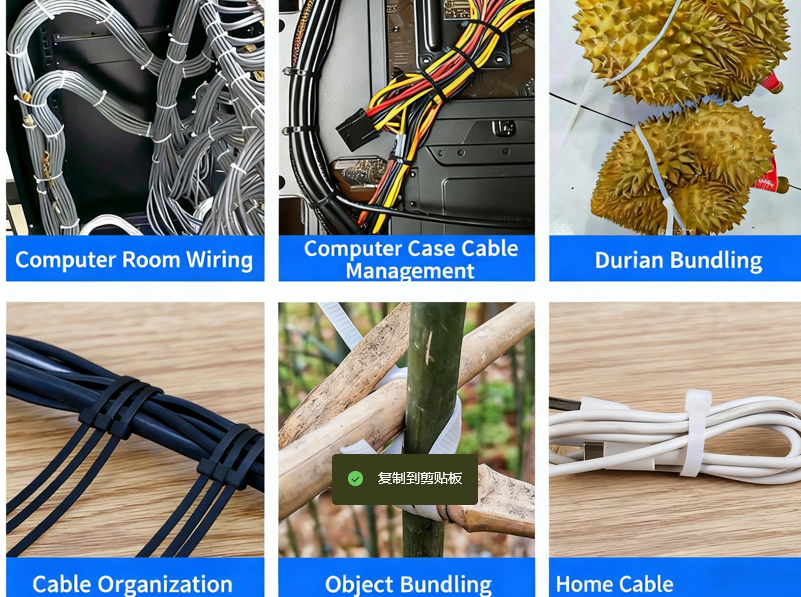

What makes engineering grade cable ties stand out isn't just what they're made from, but how they're designed for specific applications. These ties feature precise ratcheting that locks securely without slipping, even when exposed to extreme temperature changes or constant vibrations. That's why they're so important in places like airplane electronics and train signal systems where failure isn't an option. Manufacturers reinforce these ties with special features such as embedded stainless steel fibers or specially shaped heads that spread out pressure points. This helps avoid catastrophic failures when tying together thick bundles of cables or heavy battery packs. When it comes to ergonomics, designers have really thought things through. The textured tabs on these ties work well even with thick gloves on, which matters a lot in environments like oil rigs or utility companies. Their slim profile reduces accidents in automated manufacturing areas, while the angled heads and smooth tails cut down on hand strain by around 40%, according to tests done on electric car battery production lines. Whether holding together deep sea communication lines or managing power distribution in modern vehicles, these cable ties represent the perfect mix of careful engineering, smart material choices, and real world usability.

FAQ

What are the advantages of using stainless steel cable ties?

Stainless steel cable ties offer superior tensile strength, thermal stability, and corrosion resistance compared to nylon ties, making them ideal for extreme environments.

How do high-performance polymers like PEEK and ETFE compare in durability?

High-performance polymers such as PEEK and ETFE maintain their strength in high temperatures and resist UV light and chemicals, ensuring longevity in harsh environments.

Why are fire-retardant and halogen-free cable ties important?

Fire-retardant and halogen-free cable ties help prevent the spread of fires and reduce toxic emissions during combustion, meeting safety and environmental regulations.

Why is Loop Tensile Strength (LTS) not always reliable for real-world applications?

LTS does not account for dynamic forces and environmental changes that affect material performance, necessitating designs with built-in extras for safety.

How do advanced cable tie designs improve ergonomics and functionality?

Advanced designs include ratcheting precision and ergonomic features to enhance usability and reduce physical strain, ensuring reliability and efficiency in various settings.

Table of Contents

-

Material Composition: How Polymer and Metal Choices Define Cable Tie Performance

- Nylon 6/6 vs. Stainless Steel: Tensile Strength, Thermal Stability, and Corrosion Resistance

- High-Performance Polymers (PEEK, ETFE, POM): UV, Chemical, and Vibration Resistance for Harsh Environments

- Fire-Retardant, Halogen-Free, and Biodegradable Cable Tie Options for Safety and Sustainability Compliance

- Mechanical Reliability: Tensile Strength, Tension Control, and Load-Bearing Consistency

- Design Intelligence: Ratcheting Precision, Structural Reinforcement, and Application-Specific Ergonomics

-

FAQ

- What are the advantages of using stainless steel cable ties?

- How do high-performance polymers like PEEK and ETFE compare in durability?

- Why are fire-retardant and halogen-free cable ties important?

- Why is Loop Tensile Strength (LTS) not always reliable for real-world applications?

- How do advanced cable tie designs improve ergonomics and functionality?